All About Coffee by William H. Ukers (best new books to read .TXT) 📕

CHAPTER II

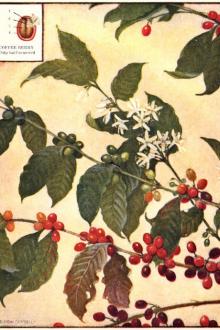

HISTORY OF COFFEE PROPAGATION

A brief account of the cultivation of the coffee plant in the Old World, and of its introduction into the New--A romantic coffee adventure Page 5

CHAPTER III

EARLY HISTORY OF COFFEE DRINKING

Coffee in the Near East in the early centuries--Stories of its origin--Discovery by physicians and adoption by the Church--Its spread through Arabia, Persia, and Turkey--Persecutions and Intolerances--Early coffee manners and customs Page 11

CHAPTER IV

INTRODUCTION OF COFFEE INTO WESTERN EUROPE

When the three great temperance beverages, cocoa, tea, and coffee, came to Europe--Coffee first mentioned by Rauwolf in 1582--Early days of coffee in Italy--How Pope Clement VIII baptized it and made it a truly Christian beverage--The first Europe

Read free book «All About Coffee by William H. Ukers (best new books to read .TXT) 📕» - read online or download for free at americanlibrarybooks.com

- Author: William H. Ukers

- Performer: -

Read book online «All About Coffee by William H. Ukers (best new books to read .TXT) 📕». Author - William H. Ukers

A blight in 1855–56 set back the industry, many plantations being ruined and then given over to sugar cane. After the blight had disappeared, the plantations were re-established, and prosperity continued for years. Following the American occupation of the islands in 1898, came another period of depression. With the loss of the protective tariff that had existed, prices fell to an unremunerativte figure; and the more profitable sugar cane was taken up again. After 1912, the increased demand for coffee, with higher prices, led again to hopes for the future of the industry. Planting was encouraged; and it has been demonstrated that from lands well selected and intelligently cultivated it is possible to have a yield of from 1,200 to 2,100 pounds per acre. Improvements have also been made in pulping and milling facilities. Many of the plantations are cultivated by Japanese labor.

Exports of coffee from Hawaii to the principal countries of the world in 1920 were 2,573,300 pounds.

Philippine Islands. Spanish missionaries from Mexico are said to have carried the coffee plant to the Philippine Islands in the latter part of the eighteenth century. At first it was cultivated in the province of La Laguna; but afterward other provinces, notably Batangas and Cavite, took it up; and in a short time the industry was one of the most important in the islands. The coffee was of the arabica variety. In the middle of the eighteenth century, and after, the industry had a position of importance; several provinces produced profitable crops that contributed much to the wealth of the communities where the berry was cultivated. In those days the city of Yipa was an important trading center. In the period of its prime Philippine coffee enjoyed fine repute, especially in Spain, Great Britain, and China (at Hong Kong), those three countries being the largest consumers. At one time—in 1883 and 1884—the annual export was 16,000,000 pounds, which demonstrates the importance of the industry at the peak of its prosperity. The leaf blight appeared on the island about 1889, causing destruction from which there has not yet been complete recovery. The export of 3,086 pounds in 1917 shows the depths into which the industry had fallen.

The Bureau of Agriculture at Manila announced in 1915 that an effort was to be made to re-habilitate the coffee industry of the islands. Nothing came of the effort, which died a-borning. Since then, several attempts to introduce disease-resisting varieties of coffee from Java have failed because of lack of interest on the part of the natives.

Despite the misfortunes that have overwhelmed it in the past and are now retarding its growth, it is still believed that the industry in these islands may be re-habilitated. Conditions of soil and climate are favorable; land and labor are cheap, abundant, and dependable: railroads run into the best coffee regions, and good cart roads are in process of construction. Some plantations of consequence are still in existence, and serious consideration is being given to their development and to increasing their number.

Guam. Coffee is one of the commonest wild plants on the little island of Guam. It grows around the houses like shade trees or flowering shrubs, and nearly every family cultivates a small patch. Climate and soil are favorable to it; and it flourishes, with abundant crops, from the sea-level to the tops of the highest hills. The plants are set in straight rows, from three and a half to seven feet apart, and are shaded by banana trees or by cocoanut leaves stuck in the ground. There is no production for export, scarcely enough for home consumption.

Other Pacific Islands. Other islands of the Pacific do not loom large in coffee growing, though New Caledonia gives promise as a producer, exporting 1,248,024 pounds in 1916, most of which was robusta. Tahiti produces a fair coffee, but in no commercial quantity. In the Samoan group there are plantations, small in number, in size, and in amount of production. Several islands of the Fiji group are said to be well adapted to coffee, but little is grown there and none for export.

Drying Grounds, Fazenda Santa Adelaide, Ribeirao Preto Drying Grounds, Fazenda Santa Adelaide, Ribeirao Preto

COFFEE PREPARATION IN SÃO PAULO, BRAZIL Chapter XXI PREPARING GREEN COFFEE FOR MARKET

Early Arabian methods of preparation—How primitive devices were replaced by modern methods—A chronological story of the development of scientific plantation machinery, and the part played by British and American inventors—The marvelous coffee package, one of the most ingenious in all nature—How coffee is harvested—Picking—Preparation by the dry and the wet methods—Pulping—Fermentation and washing—Drying—Hulling; or peeling, and polishing—Sizing, or grading—Preparation methods of different countries

La Roque[316], in his description of the ancient coffee culture, and the preparation methods as followed in Yemen, says that the berries were permitted to dry on the trees. When the outer covering began to shrivel, the trees were shaken, causing the fully matured fruits to drop upon cloths spread to receive them. They were next exposed to the sun on drying-mats, after which they were husked by means of wooden or stone rollers. The beans were given a further drying in the sun, and then were submitted to a winnowing process, for which large fans were used.

Development of Plantation Machinery

The primitive methods of the original Arab planters were generally followed by the Dutch pioneers, and later by the French, with slight modifications. As the cultivation spread, necessity for more effective methods of handling the ripened fruit mothered inventions that soon began to transform the whole aspect of the business. Probably the first notable advance was in curing, when the West Indian process, or wet method, of cleaning the berries was evolved.

About the time that Brazil began the active cultivation of coffee, William Panter was granted the first English patent on a "mill for husking coffee." This was in 1775. James Henckel followed with an English patent, granted in 1806, on a coffee drier, "an invention communicated to him by a certain foreigner." The first American to enter the lists was Nathan Reed of Belfast, Me., who in 1822 was granted a United States patent on a coffee huller. Roswell Abbey obtained a United States patent on a huller in 1825; and Zenos Bronson, of Jasper County, Ga., obtained one on another huller in 1829. In the next few years many others followed.

John Chester Lyman, in 1834, was granted an English patent on a coffee huller employing circular wooden disks, fitted with wire teeth. Isaac Adams and Thomas Ditson of Boston brought out improved hullers in 1835; and James Meacock of Kingston, Jamaica, patented in England, in 1845, a self-contained machine for pulping, dressing, and sorting coffee.

William McKinnon began, in 1840, the manufacture of coffee plantation machinery at the Spring Garden Iron Works, founded by him in 1798 in Aberdeen, Scotland. He died in 1873; but the business continues as Wm. McKinnon & Co., Ltd.

About 1850 John Walker, one of the pioneer English inventors of coffee-plantation machinery, brought out in Ceylon his cylinder pulper for Arabian coffee. The pulping surface was made of copper, and was pierced with a half-moon punch that raised the cut edges into half circles.

The next twenty years witnessed some of the most notable advances in the development of machinery for plantation treatment, and served to introduce the inventions of several men whose names will ever be associated with the industry.

John Gordon & Co. began the manufacture in London of the line of plantation machinery still known around the world as "Gordon make" in 1850; and John Gordon was granted an English patent on his improved coffee pulper in 1859.

Robert Bowman Tennent obtained English (1852) and United States (1853) patents on a two-cylinder pulper.

George L. Squier began the manufacture of plantation machinery in Buffalo, N.Y., in 1857. He was active in the business until 1893, and died in 1910. The Geo. L. Squier Manufacturing Co. still continues as one of the leading American manufacturers of coffee-plantation machinery.

Marcus Mason, an American mechanical engineer in San José, Costa Rica, invented (1860) a coffee pulper and cleaner which became the foundation stone of the extensive plantation-machinery business of Marcus Mason & Co., established in 1873 at Worcester, Mass.

Much favored in Ceylon and India

John Walker was granted (1860) an English patent on a disk pulper in which the copper pulping surface was punched, or knobbed, by a blind punch that raised rows of oval knobs but did not pierce the sheet, and so left no sharp edges. During Ceylon's fifty years of coffee production, the Walker machines played an important part in the industry. They are still manufactured by Walker, Sons & Co., Ltd., of Colombo, and are sold to other producing countries.

Alexius Van Gulpen began the manufacture of a green-coffee-grading machine at Emmerich, Germany, in 1860.

Following Newell's United States patents of 1857–59, sixteen other patents were issued on various types of coffee-cleaning machines, some designed for plantation use, and some for treating the beans on arrival in the consuming countries.

Largely used in India and Ceylon

James Henry Thompson, of Hoboken, and John Lidgerwood were granted, in 1864, an English patent on a coffee-hulling machine. William Van Vleek Lidgerwood, American chargé d'affaires at Rio de Janeiro, was granted an English patent on a coffee hulling and cleaning machine in 1866. The name Lidgerwood has long been familiar to coffee planters. The Lidgerwood Manufacturing Co., Ltd., has its headquarters in London, with factory in Glasgow. Branch offices are maintained at Rio de Janeiro, Campinas, and in other cities in coffee-growing countries.

Probably the name most familiar to coffee men in connection with plantation methods is Guardiola. It first appears in the chronological record in 1872, when J. Guardiola, of Chocola, Guatemala, was granted several United States patents on machines for pulping and drying coffee. Since then, "Guardiola" has come to mean a definite type of rotary drying machine that—after the original patent expired—was manufactured by practically all the leading makers of plantation machinery. José Guardiola obtained additional United States patents on coffee hullers in 1886.

William Van Vleek Lidgerwood, Morristown, N.J., was granted an English patent on an improved coffee pulper in 1875.

Several important cleaning and grading machinery patents were granted by the United States (1876–1878) to Henry B. Stevens, who assigned them to the Geo. L. Squier Manufacturing Co., Buffalo, N.Y. One of them was on a separator, in which the coffee beans were discharged from the hopper in a thin stream upon an endless carrier, or apron, arranged at such an inclination that the round beans would roll by force of gravity down the apron, while the flat beans

Comments (0)