All About Coffee by William H. Ukers (best new books to read .TXT) 📕

CHAPTER II

HISTORY OF COFFEE PROPAGATION

A brief account of the cultivation of the coffee plant in the Old World, and of its introduction into the New--A romantic coffee adventure Page 5

CHAPTER III

EARLY HISTORY OF COFFEE DRINKING

Coffee in the Near East in the early centuries--Stories of its origin--Discovery by physicians and adoption by the Church--Its spread through Arabia, Persia, and Turkey--Persecutions and Intolerances--Early coffee manners and customs Page 11

CHAPTER IV

INTRODUCTION OF COFFEE INTO WESTERN EUROPE

When the three great temperance beverages, cocoa, tea, and coffee, came to Europe--Coffee first mentioned by Rauwolf in 1582--Early days of coffee in Italy--How Pope Clement VIII baptized it and made it a truly Christian beverage--The first Europe

Read free book «All About Coffee by William H. Ukers (best new books to read .TXT) 📕» - read online or download for free at americanlibrarybooks.com

- Author: William H. Ukers

- Performer: -

Read book online «All About Coffee by William H. Ukers (best new books to read .TXT) 📕». Author - William H. Ukers

C.F. Hargreaves, of Rio de Janeiro, was granted an English patent on machinery for hulling, polishing, and separating coffee, in 1879.

The first German patent on a coffee drying apparatus was granted to Henry Scolfield, of Guatemala, in 1880.

In 1885 Evaristo Conrado Engelberg of Piracicaba, São Paulo, Brazil, invented an improved coffee huller which, three years later, was patented in the United States. The Engelberg Huller Co. of Syracuse, N.Y., was organized the same year (1888) to make and to sell Engelberg machines.

Walker Sons & Co., Ltd., began, in 1886, experimenting in Ceylon with a Liberian disk pulper that was not fully perfected until twelve years later.

Another name, that has since become almost as well known as Guardiola, appears in the record in 1891. It is that of O'Krassa. In that year R.F.E. O'Krassa of Antigua, Guatemala, was granted an English patent on a coffee pulper. Additional patents on washing, hulling, drying, and separating machines were issued to Mr. O'Krassa in England and in the United States in 1900, 1908, 1911, 1912, and 1913.

The Fried. Krupp A.G. Grusonwerk, Magdeburg-Buckau, Germany, began the manufacture of coffee plantation machines about 1892. Among others it builds coffee pulpers and hulling and polishing machines of the Anderson (Mexican) and Krull (Brazilian) types.

Additional United States patents were granted in 1895 to Marcus Mason, assignor to Marcus Mason & Co., New York, on machines for pulping and polishing coffee. Douglas Gordon assigned patents on a coffee pulper and a coffee drier to Marcus Mason & Co. in 1904–05.

The names of Jules Smout, a Swiss, and Don Roberto O'Krassa, of Guatemala, are well known to coffee planters the world over because of their combined peeling and polishing machines.

The Huntley Manufacturing Co., Silver Creek, N.Y., began in 1896 the manufacture of the Monitor line of coffee-grading-and-cleaning machines.

The Marvelous Coffee Package

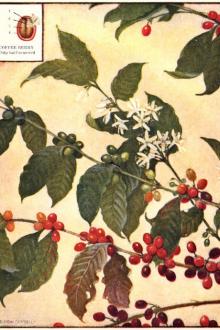

It is doubtful if in all nature there is a more cunningly devised food package than the fruit of the coffee tree. It seems as if Good Mother Nature had said: "This gift of Heaven is too precious to put up in any ordinary parcel. I shall design for it a casket worthy of its divine origin. And the casket shall have an inner seal that shall safeguard it from enemies, and that shall preserve its goodness for man until the day when, transported over the deserts and across the seas, it shall be broken open to be transmuted by the fires of friendship, and made to yield up its aromatic nectar in the Great Drink of Democracy."

To this end she caused to grow from the heart of the jasmine-like flower, that first herald of its coming, a marvelous berry which, as it ripens, turns first from green to yellow, then to reddish, to deep crimson, and at last to a royal purple.

1—For Arabian coffee (Coffea arabica). 2—For Liberian coffee (Coffea liberica). 3—Also for Arabian. 4—For Coffea canephora. 5—For Coffea robusta. 6—For larger Arabian, and for Coffea Maragogipe.

The coffee fruit is very like a cherry, though somewhat elongated and having in its upper end a small umbilicus. But mark with what ingenuity the package has been constructed! The outer wrapping is a thin, gossamer-like skin which encloses a soft pulp, sweetish to the taste, but of a mucilaginous consistency. This pulp in turn is wrapped about the inner-seal—called the parchment, because of its tough texture. The parchment encloses the magic bean in its last wrapping, a delicate silver-colored skin, not unlike fine spun silk or the sheerest of tissue papers. And this last wrapping is so tenacious, so true to its guardianship function, that no amount of rough treatment can dislodge it altogether; for portions of it cling to the bean even into the roasting and grinding processes.

Drying Grounds, Pulping House, and Fermentation Vats, Boa Vista. Brazil

Pulping House and Fermentation Tanks, Costa Rica

Pulping House and Fermentation Tanks, Costa Rica

COFFEE PREPARATION IN CENTRAL AND SOUTH AMERICA

Granada Unpulped Coffee Separator Granada Unpulped Coffee Separator

Shown in combination with a Guatemala coffee pulper

Coffee is said to be "in the husk," or "in the parchment," when the whole fruit is dried; and it is called "hulled coffee" when it has been deprived of its hull and peel. The matter forming the fruit, called the coffee berry, covers two thin, hard, oval seed vessels held together, one to the other, by their flat sides. These seed vessels, when broken open, contain the raw coffee beans of commerce. They are usually of a roundish oval shape, convex on the outside, flat inside, marked longitudinally in the center of the flat side with a deep incision, and wrapped in the thin pellicle known as the silver skin. When one of the two seeds aborts, the remaining one acquires a greater size, and fills the interior of the fruit, which in that case, of course, has but one cellule. This abortion is common in the arabica variety, and produces a bean formerly called gragé coffee, but now more commonly known as peaberry, or male berry.

The various coverings of the coffee beans are almost always removed on the plantations in the producing countries. Properly to prepare the raw beans, it is necessary to remove the four coverings—the outer skin, the sticky pulp, the parchment, or husk, and the closely adhering silver skin.

There are two distinct methods of treating the coffee fruits, or "cherries." One process, the one that until recent years was in general use throughout the world, and is still in many producing countries, is known as the dry method. The coffee prepared in this way is sometimes called "common," "ordinary," or "natural," to distinguish it from the product that has been cleaned by the wet or washed method. The wet method, or, as it is sometimes designated, the "West Indian process" (W.I.P.) is practised on all the large modern plantations that have a sufficient supply of water.

In the wet process, the first step is called pulping; the second is fermentation and washing; the third is drying; the fourth is hulling or peeling; and the last, sizing or grading. In the dry process, the first step is drying; the second hulling; and the last, sizing or grading.

Harvesting

The coffee cherry ripens about six to seven months after the tree has flowered, or blossomed; and becomes a deep purplish-crimson color. It is then ready for picking. The ripening season varies throughout the world, according to climate and altitude. In the state of São Paulo, Brazil, the harvesting season lasts from May to September; while in Java, where three crops are produced annually, harvesting is almost a continuous process throughout the year. In Colombia the harvesting seasons are March and April, and November and December. In Guatemala the crops are gathered from October through December; in Venezuela, from November through March. In Mexico the coffee is harvested from November to January; in Haiti the harvest extends from November to March; in Arabia, from September to March; in Abyssinia, from September through November. In Uganda, Africa, there are two main crops, one ripening in March and the other in September, and picking is carried on during practically every month except December and January. In India the fruit is ready for harvesting from October to January.

Tandem Coffee Pulper of English Make

Being a combination of a Bon-Accord-Valencia pulper with a Bon-Accord repassing machine

Picking

The general practise throughout the world has been to hand-pick the fruit; although in some countries the cherries are allowed to become fully ripe on the trees, and to fall to the ground. The introduction of the wet method of preparation, indeed, has made it largely unnecessary to hand-pick crops; and the tendency seems to be away from this practise on the larger plantations. If the berries are gathered promptly after dropping, the beans are not injured, and the cost of harvesting is reduced.

The picking season is a busy time on a large plantation. All hands join in the work—men, women and children; for it must be rushed. Over-ripe berries shrink and dry up. The pickers, with baskets slung over their shoulders, walk between the rows, stripping the berries from the trees, using ladders to reach the topmost branches, and sometimes even taking immature fruit in their haste to expedite the work. About thirty pounds is considered a fair day's work under good conditions. As the baskets are filled, they are emptied at a "station" in that particular unit of the plantation; or, in some cases, directly into wagons that keep pace with the pickers. The coffee is freed as much as possible of sticks, leaves, etc., and is then conveyed to the preparation grounds.

A space of several acres is needed for the various preparation processes on the larger plantations; the plant including concrete-surfaced drying grounds, large fermentation tanks, washing vats, mills, warehouses, stables, and even machine shops. In Mexico this place is known as the beneficio.

Washed and Unwashed Coffee

Where water is plenty, the ripe coffee cherries are fed by a stream of water into a pulping machine which breaks the outer skins, permitting the pulpy matter enveloping the beans to be loosened and carried away in further washings. It is this wet separation of the sticky pulp from the beans, instead of allowing it to dry on them, to be removed later with the parchment in the hulling operation, that makes the distinction between washed and unwashed coffees. Where water is scarce the coffees are unwashed.

Either method being well done, does washing improve the strength and flavor? Opinions differ. The soil, altitude, climatic influences, and cultivation methods of a country give its coffee certain distinctive drinking qualities. Washing immensely improves the appearance of the bean; it also reduces curing costs. Generally speaking, washed coffees will always command a premium over coffees dried in the pulp.

Continuous Working Horizontal Coffee Washer Continuous Working Horizontal Coffee Washer

Whether coffee is washed or not, it has to be dried; and there is a kind of fermentation that goes on during washing and drying, about which coffee planters have differing ideas, just as tea planters differ over the curing of tea leaves. Careful scientific study is needed to determine how much, if any, effect this fermentation has on the ultimate cup value.

Preparation by the Dry Method

The dry method of preparing the berries is not only the older method, but is considered by some operators as providing a distinct advantage over the wet process, since berries of different degrees of ripeness can be handled at the same time. However, the success of this method is dependent largely on the continuance of clear warm weather over quite a length of time, which can not always be counted on.

In this process the berries are spread in a thin layer on open drying grounds, or barbecues, often having cement or brick surfaces. The berries are turned over several times a day in order to permit the sun and wind thoroughly to dry all portions. The sun-drying process lasts about three weeks; and after the first three days of this period, the berries must be protected from dews and rains by covering them with tarpaulins, or by raking them into heaps under cover. If the berries are not spread out, they heat, and the silver skin sticks to the coffee bean, and frequently discolors it. When thoroughly dry, the berries are stored, unless the husks (outer skin and inner parchment) are to be removed at once. Hot air, steam, and

Comments (0)