All About Coffee by William H. Ukers (best new books to read .TXT) 📕

CHAPTER II

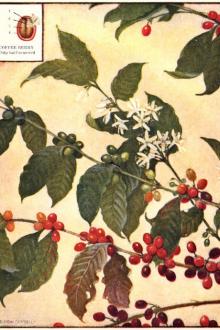

HISTORY OF COFFEE PROPAGATION

A brief account of the cultivation of the coffee plant in the Old World, and of its introduction into the New--A romantic coffee adventure Page 5

CHAPTER III

EARLY HISTORY OF COFFEE DRINKING

Coffee in the Near East in the early centuries--Stories of its origin--Discovery by physicians and adoption by the Church--Its spread through Arabia, Persia, and Turkey--Persecutions and Intolerances--Early coffee manners and customs Page 11

CHAPTER IV

INTRODUCTION OF COFFEE INTO WESTERN EUROPE

When the three great temperance beverages, cocoa, tea, and coffee, came to Europe--Coffee first mentioned by Rauwolf in 1582--Early days of coffee in Italy--How Pope Clement VIII baptized it and made it a truly Christian beverage--The first Europe

Read free book «All About Coffee by William H. Ukers (best new books to read .TXT) 📕» - read online or download for free at americanlibrarybooks.com

- Author: William H. Ukers

- Performer: -

Read book online «All About Coffee by William H. Ukers (best new books to read .TXT) 📕». Author - William H. Ukers

To roast coffee by coal or coke usually requires from twenty-five to thirty minutes, depending on the moisture-content of the beans; whether they are spongy or flinty; whether a light, medium, or dark roast is desired; and on the skill of the operator. Gas roasting requires from fifteen to twenty minutes. The quicker the roast, the better the coffee, is the opinion of many trade leaders, one of whom[325] says:

It is a growing belief that in roasts of short duration the largest percentage of the aromatic properties is retained. A slow roast has the effect of baking and does not give full development; also, slow roasts seldom produce bright roasts, and they usually make the coffee hard instead of brittle, even when the color standard has been attained.

While coffees of widely varying degrees of moisture require somewhat different treatment, the consensus of opinion is that the best results are obtained from a slow fire at the beginning, until some of the moisture has been driven off, when the stronger application of heat may be given for development. An intense heat in the beginning often results in "tipping", or charring, the little germ at the end, the most sensitive part of the bean.

Scorched beans have been caught at some point in the cylinder, often in a bent flange. Burning on one face, sometimes called "kissing the cheeks", is caused by the too rapid revolution of the cylinder, so that some of the coffee "carries over". In the best practise, crowding of cylinders is avoided; many roasters making it a rule not to exceed ninety percent of the rated capacity of the cylinder.

Those operating gas roasters may effect a fuel economy by running a low grade coffee in the cylinder after the last roast has been drawn and the gas extinguished; five minutes' revolution absorbs the heat and drives off a proportion of moisture. The coffee, which may then be left in the cylinder, requires less time and fuel in the morning, and the roast is finished while the cylinder is warming up. Double roasting brightens a roast, but is a detriment to the cup quality. A dull roasting coffee may be improved by revolving the green coffee in a cylinder without heat for twenty minutes, which has the effect of milling.

The use of a small amount of water upon roasts gives better control by checking the roast at the proper point—the crucial time of its greatest heat; also, it swells and brightens the coffee, and tends to close the outer pores. While the addition of water is open to abuse, few roasters have soaked their coffees enough to offset the natural shrinkage as much as three or four percent. Such practise would result greatly to the detriment of the cup quality.

There is no universal standard for the degree to which coffee should be roasted. In the United States, there are demands for all degrees; from the light roast, in favor in England, to the extremely dark roast in vogue in France, Italy, Brazil, Turkey, and in the producing countries. The North American trade recognizes these different roasts: light, cinnamon, medium, high, city, full city, French, and Italian. The city roast is a dark bean, while full city is a few degrees darker. In the French roast, the bean is cooked until the natural oil appears on the surface; and in the Italian, it is roasted to the point of actual carbonization, so that it can be easily powdered. Germany likes a roast similar to the French type; while Scandinavia prefers the high Italian roast.

In the United States, the lighter roast is favored on the Pacific coast; the darkest, in the South; and a medium-colored roast, in the Eastern states. The cinnamon roast is most favored by the trade in Boston.

While coffee roasting in the United States usually takes from fifteen to thirty minutes, depending on the fuel and the machine employed, manufacturers of gas machines on the German market claim to roast it in superior fashion in from three and a half to ten minutes.[326] This subject is discussed more in detail in chapter XXXIV.

Coffee loses weight during the roasting process, the loss varying according to the degree of roasting and the nature of the bean. Coffee roasters figure, however, that the average loss is sixteen percent of the weight of the green bean. It has been estimated that one hundred pounds of coffee in the cherry produces twenty-five pounds in the parchment; that one hundred pounds in parchment produces eighty-four pounds of cleaned coffee; and that one hundred pounds of cleaned coffee produces eighty-four pounds roasted.

There are four of these machines. The cylinders are twelve feet in diameter, six feet deep, and can roast 5,000 pounds of coffee every half-hour. The hard-coal brick furnace is seen at the left, from which a blower forces the heated air through a pipe into the revolving cylinder of coffee. The coffee is fed from above and is emptied into the cooling pans beneath

An Eight-Cylinder Gas Coffee-Roasting Plant An Eight-Cylinder Gas Coffee-Roasting Plant

A view of Reid, Murdoch & Co.'s roasting room, Chicago, equipped with Monitor machines

During the roasting process the coffee undergoes a great chemical change. After it has been in the cylinder a short time, the color of the bean becomes a yellowish brown, which gradually deepens as it cooks. Likewise, as the beans become heated, they shrivel up until about half done, or at the "developing" point. At this stage, they begin to swell, and then "pop open", increasing fifty percent in bulk.[327] This is when the experienced roasterman turns on all the heat he can command to finish the roasting as quickly as possible.

"Dry" and "Wet" Roasts

At frequent intervals, he thrusts his "trier"—an instrument shaped somewhat like an elongated spoon—into the cylinder, and takes out a sample of coffee to compare with his type sample. When the coffee is done, he shuts off the heat and checks the cooking by reducing the temperature of the coffee and of the cylinder as quickly as can be done. In the wet roast method he will spray the coffee, while the cylinder is still revolving, with three to four quarts of water to every 130 pounds of coffee. In the dry method he depends altogether upon his cooling apparatus.

Roasters generally are not in favor of the excessive watering of coffee in and after the roasting process for the purpose of reducing shrinkage. "Heading" the coffee, or checking the roast before turning it out of the roasting cylinder, is quite another matter and is considered legitimate. Where coffees are watered in the cylinder at the close of the roast to reduce the shrinkage, it is possible to get back only about four percent of the shrinkage by such treatment and the practise is frowned upon by the best roasters.

Generally speaking, water is turned into the roasting cylinder to quench the roast. The amount varies with the style of machine, whether gas or coal. Usually the water turns to steam, and the result is not an absorption of the water but a momentary checking of the roast with a tendency to swell and to brighten the coffee. This is, comparatively speaking, a "dry roast", but not an absolutely dry roast. It is doubtful if more than one percent of American coffee roasters employ an absolutely "dry" roast—it does not give satisfactory results. The word has been abused for advertising purposes. Of course, a dry roasted coffee is a better article for making a satisfactory beverage than one that has been soaked with water; but the word "dry" must be given a definite meaning, which the trade generally will agree to uphold, if it is to have any real meaning or value to the consumer. Until some standard for roasted coffee shall be established, it is to be feared the term "dry roast" will continue to be used for coffee roasted by almost any other process.

Upper-Story View of a Jubilee Plant, Showing Roaster, Cooler, and Stoner Equipment

The parts under roasting-room floor are shown in the illustration below

Lower-Story View of the Same Plant from About the Same Angle Lower-Story View of the Same Plant from About the Same Angle

Showing connection from floor hopper to stoner on the left, and suspended bucket-elevator boot with four-bag dump hopper on the right

COMPLETE GAS COFFEE-PLANT INSTALLATION

The Bureau of Chemistry held a hearing in 1914 at Washington, at which the question of a ruling on watering coffees was discussed. The trade was well represented, but no agreement was reached. It was deemed inadvisable to make a definite rule on the watering of coffee; because the water content can not be controlled, as the bean starts to absorb moisture as soon as it leaves the roaster.

On Roasting Coffee Efficiently

A.L. Burns, New York, is well qualified to speak on this subject. He says:

Roasting coffee is not so difficult a matter as is often claimed by operators and "experts" who seek thus to magnify their importance; but it is nevertheless a process about which a great deal may be learned in the school of practical experience. With one of our modern machines anybody with ordinary intelligence and nerve can take off a roast after one trial which would pass muster in many establishments, but that same person applying himself to the roasting job for a week will either be turning out vastly better roasts or will have demonstrated that he never can excel as a roasterman.

Modern coffee roasting machines provide for easy control of the heat (from coal, coke, or gas fuel), for constantly mixing the coffee in such a manner that the heat is transmitted uniformly to the entire batch, for carrying away all steam and smoke rapidly, for easy testing of the progress of the roast, and for immediate discharge when desired. The operator's problem therefore is the regulation of the heat and deciding just when the desired roasting has been accomplished.

If all coffees were alike, roasting would soon be almost automatic. In some plants most of the work is on one uniform grade or blend. But coffees which vary greatly in moisture-content, in flinty or spongy nature, and in various other characteristics, will puzzle the operator until he establishes a personal acquaintance with them in various combinations in repeated roasting operations. The roasterman therefore must be able to observe closely, to draw sensible conclusions, and to remember what he learns. Roasting coffee is work of a sort which anybody can do, which a few people can do really well, and no one so well but that further improvement is possible.

There is no absolute standard of what the best roasting results are. Some dealers want the coffee beans swelled

Comments (0)